Smart Aquaculture Management

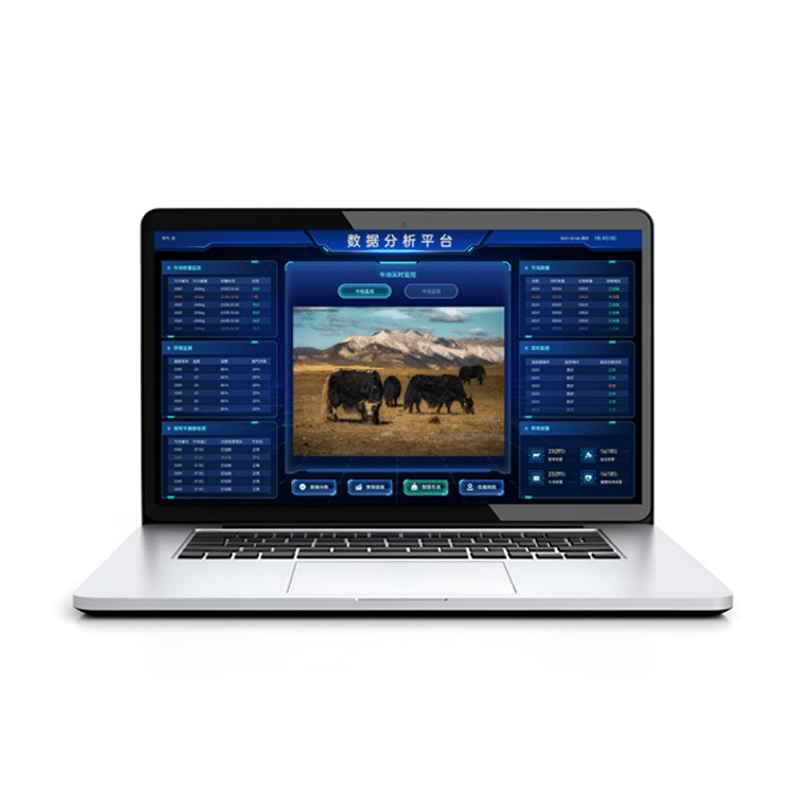

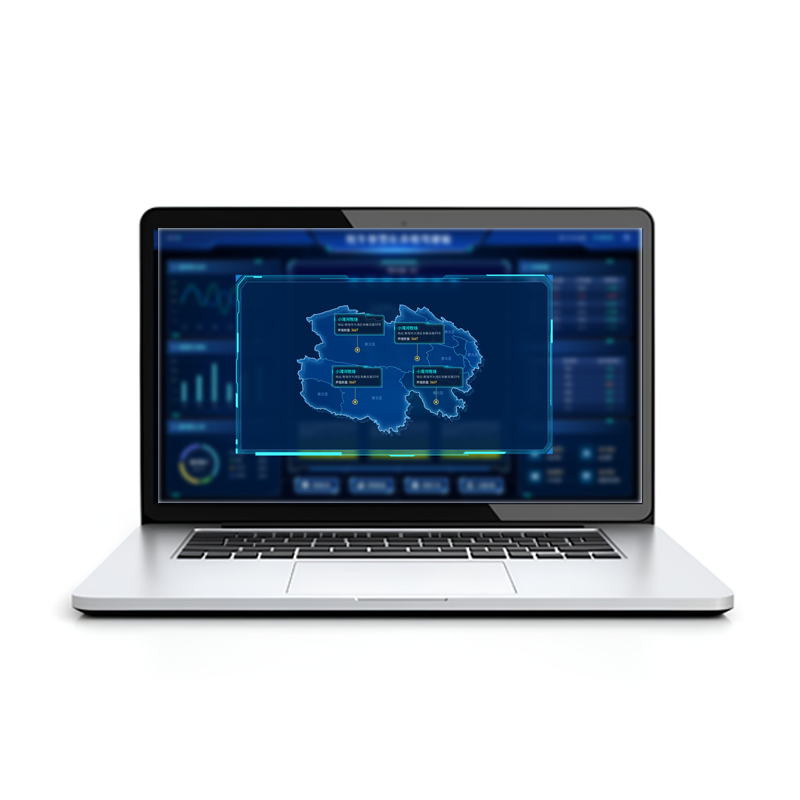

Real-time monitoring of every single livestock animal, comprehensive lifecycle management of all farms with no blind spots.

Customer Pain Points

From technology implementation, operational management, and cost control to herd adaptation, smart farming drives the industry's digital transformation while presenting multi-dimensional challenges for farmers of varying scales. These challenges manifest as follows:

1. Loose individual management

In traditional livestock farming, data such as individual animal health status, feeding frequency, and breeding cycles are recorded manually and imprecisely, resulting in a lack of accurate tracking throughout the entire life cycle. This not only significantly undermines the scientific basis for breeding pairings, leading to large fluctuations in litter sizes, but also causes inadequate control over growth conditions prior to market readiness. Ultimately, this impacts the weight and quality consistency of finished livestock, making it difficult to consistently meet high-standard purchasing requirements.

2. Serious waste of resources

Feed allocation relies on empirical estimates, frequently resulting in overfeeding that wastes resources or underfeeding that stunts growth. Medication use lacks data-driven guidance, leading to over-treatment for minor ailments or insufficient dosages. Energy consumption (e.g., temperature control equipment) is also manually adjusted based on intuition, causing additional water and electricity waste. These data-deficient practices cumulatively increase per-head livestock production costs by 15%-20% compared to precision management, squeezing profit margins.

3. Delayed Risk Response

The lack of real-time monitoring for environmental indicators such as temperature, humidity, and ammonia levels within livestock housing makes it difficult to promptly detect early signs of disease, such as decreased appetite and lethargy. By the time abnormalities are identified, the disease has often spread to small groups, not only increasing treatment costs but also potentially causing delayed market readiness due to disease control measures. This can even lead to mass casualties, resulting in direct losses of tens of thousands of yuan while disrupting subsequent breeding plans.

4. Low labor efficiency

Manual inspections of individual livestock barns take 1-2 hours, with data statistics requiring manual spreadsheet organization and traceability records relying on paper ledgers for archiving. This process is not only time-consuming and labor-intensive but also prone to data errors and omissions. For instance, weight measurement errors may exceed 5%, and data cannot be synchronized in real-time to decision-making platforms. This results in a 1-2 day delay in implementing feeding adjustments, disease response measures, and other interventions, often missing the optimal window for intervention.

5. Weak traceability system

From breeding stock and feed batches to medication records and growth cycles, the entire process lacks digital data storage. Should product quality issues arise, it becomes impossible to swiftly pinpoint the faulty link in the chain. This not only fails to meet regulatory compliance and traceability requirements but also prevents demonstrating the safety of farming practices to consumers. Consequently, brand trust erodes, undermining eligibility for premium market access.

Solution Description and Key Products

This solution centers on “individual-level precision monitoring + full lifecycle management,” deeply integrating Fenglan's intelligent product modules to build an efficient smart farming system. The modules utilize high-precision IoT devices to collect real-time key data on individual livestock health, feeding, and reproduction, establishing a seamless data chain from breeding to market readiness. They simultaneously monitor environmental temperature, humidity, and ammonia levels while enabling intelligent adjustments, with algorithms issuing early warnings for disease and anomaly risks. Simultaneously, it replaces manual inspection and data collection, reducing errors and boosting efficiency. This enables precise material dispensing to cut costs, establishes a comprehensive traceability system to meet compliance and brand trust requirements, and fully empowers farms with refined management capabilities.

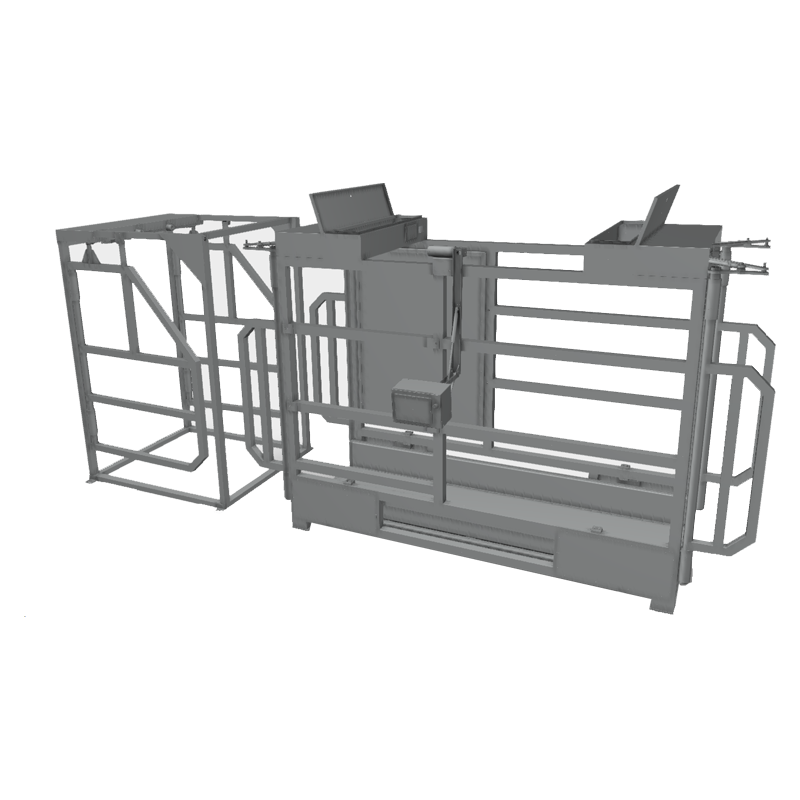

Hardware products

Delivering core value to our customers

1. Real-time precise positioning

The collar utilizes dual-mode GPS and BeiDou positioning to accurately track livestock locations. Herders can monitor their herds' whereabouts via mobile devices or system maps without leaving home, significantly reducing the labor costs associated with manually searching for cattle.

2. Fitness and Health Monitoring

Collars collect activity data from grazing livestock. On the platform side, this activity data can be used to assess the health status of grazing animals—detecting illness or death—thereby reducing unnatural mortality rates among cattle.

3. Electronic Fence Management

By integrating positioning technology to establish electronic fences, the system automatically alerts herders when livestock approach or cross boundaries. This enables remote management of herd movement ranges, reducing the risk of livestock loss and saving recovery costs.

Benchmark Case